What if scientists no longer rely on scarce organ donations, but can build healthy new organs quickly and cheaply in the laboratory, using the patient’s own cells as raw materials?

In the past 15 years or so, the dream promotes investment and research in the field of biological 3D printing. Biological 3D printing technology is to make biological units(cells/proteins/DNA, etc.) and biological materials according to the requirements of bionic morphology, biological structure or biological function, cell-specific microenvironment, etc., using “three-dimensional printing” technical means to produce personalized in vitro three-dimensional structure model or three-dimensional biological functional structure.

Its scientific research, technical application, and industrial development are widely involved in the following aspects: the development and manufacturing of biological 3D printing equipment and biological ink, manufacturing of high-end medical equipment, manufacturing of complex tissue engineering scaffolds, manufacturing of functional structures in vitro biology, manufacturing of biological/pathological/pharmacological models and new drug testing models, etc.

As an emerging cross-cutting frontier technology field, biological 3D printing is currently receiving unprecedented strategic attention in many countries.

Application of bio 3D printing technology

According to the different characteristics of the biomaterials used, the Bio3D Printing Center of Tsinghua University classifies them into 4 levels.

Level 1

Printing materials without biocompatibility requirements can be used in 3D printed in vitro case models, surgical guides, 3D printed in vitro prostheses or orthopedic assistive devices, etc. This level of application greatly exerts the advantages of 3D printing in personalized customization Advantages, help relevant patients tailor-made relevant surgical models or treatment tools, so that patients can get better treatment.

Level 2

The printing is biocompatible, but non-degradable materials. Such printed products can be used as permanent implants in the body. The materials can be such as titanium alloys metals, or inert polymers materials. T3D printed metal implant manufacturer(Akcome Medical)has obtained multiple CFDA marketing licenses, and the product has been applied clinically.

Level 3

To print bio-materials with good biocompatibility and degradability, the main application field is to print tissue engineering scaffolds. In addition. It requires printed implants not only to be compatible with the body but also to have biodegradable properties and to promote the growth and healing of defective tissues in the body over a period of time.

The original 3D printing low-temperature deposition manufacturing technology created by the Biomanufacturing Center of Tsinghua University integrates the advantages of biological 3D printing and freeze-drying microscopic pore-making technology. It can achieve both macroscopic controllable pores(100 microns)and microscopic microfilament pores.

3D printing of tissue engineering scaffolds improves the cell planting rate in the scaffolds, which is more conducive to the growth of cells inside the scaffolds and the realization of tissue functions. It has been applied well in the fields of bone tissue engineering scaffolds and has begun to transform into clinical practice.

Level 4

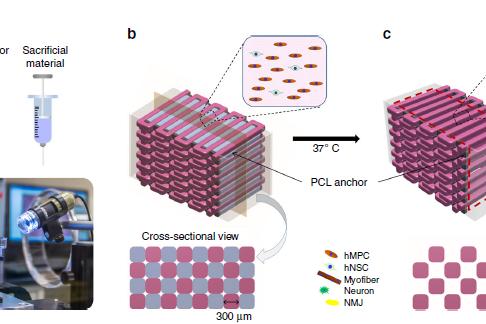

Cells 3D printing technology can directly use cells, proteins, and other biologically active materials(proteins, DNA, growth factors)as the basic units. It directly constructs in vitro biological structures, tissues, or organ models.

Technical challenges of cell 3D printing

Cells(biological)3D printing technology is currently the most cutting-edge technology, and it is also the largest potential technology for organ printing. During the printing process, the cells will inevitably endure a certain amount of mechanical force and even cause certain damage. Therefore, the realization of cell 3D printing technology is full of various technical challenges. The technical challenges of cell 3D printing mainly include the following aspects:

Can the material be printed?

First of all, we must choose the biological material/biological ink that can be printed by the biological 3D printer. Different printing processes have different requirements for the viscosity of the biological link. The biological ink with too low viscosity or high viscosity is difficult to be printed. Therefore, the first challenge for cell 3D printing is to find bio-inks that can be printed.

Can a 3D structure be constructed?

Not all printed bio-inks can build 3D structures. To print high-resolution 3D complex cell structures, cell printing inks need to increase the viscosity of the printing inks. It needs to increase the gel capacity of the bio-inks to maintain the mechanical properties of stacked structures.

Can the cells survive?

Increasing the viscosity of the cell printing ink will result in an increased unit’s shearing force during the printing process. And it will lead to a decrease in the survival rate of the cells after printing. Therefore, controlling the viscosity of the cell printing ink during the printing process(neither too high nor too low). And find a suitable viscoelastic interval for the cell printing ink is to achieve good cell 3D printing important step. Such as good formability and biological performance.

Is it functional?

The newly printed 3D cell structure is just a 3D combination of cells and biological materials and does not form tissue features. Therefore, the printed 3D cell structure must undergo appropriate culture conditions to form tissue functionality. This link needs to ensure the biocompatibility, mechanical properties, and functionality of biological materials, adequate supply culture media, and adequate discharge waste. Even some tissues require specific bioreactors to achieve their functionality through fluid, force, or electrical stimulation.

In summary, cell 3D printing is full of different or even contradictory technical challenges, and requires multidisciplinary background knowledge and experience to solve these problems.

Four classification of cell 3D printing technology

Inkjet cell printing technology

Ink-jet cell printing is based on the printing principle of ordinary ink-jet printers, using thermal bubbles or piezoelectric volume changes to squeeze the cell ink in the ink cartridge to discretely produce and eject droplets of cell ink containing cells [1]. The nozzle diameter of inkjet printers is only tens of microns, which can perform high-precision cell printing. However, due to the relatively small nozzle diameter, it is difficult for inkjet cell printing to discretely print high-viscosity cell ink, which makes it difficult for this technology to directly print 3D biological solid models. Furthermore, the generation of thermal bubbles and the deformation of the piezoelectric will certainly damage the cells, and it is necessary to better control the printing process parameters. Representative research institutions include Professor Boland’s research group at the University of Texas.

Micro-extrusion cell 3D printing technology

Micro-extrusion cell three-dimensional printing technology uses mechanical force or air pressure to directly extrude biological materials and cells directly through a micro-nozzle to construct a three-dimensional biological structure [2,3]. Since the nozzle diameter of the commonly used micro-extruded cell printer is in the hundreds of microns with general printing accuracy, but the extruded process can print high viscoelastic biological ink, easy to realize the construction of 3D biological entities. In addition, this technology increases the size of each discrete unit printed while sacrificing accuracy, which indirectly improves printing efficiency and cell survival rate. Representative research institutions include the research group of Professor Sun Wei from the Biomanufacturing Center of THU and the research group of Professor Jennifer Lewis from Harvard.

Laser direct writing cell printing technology

Laser direct writing cell printing technology refers to the use of light pressure to control the arrangement of cells into a high-precision spatial structure. Its accuracy can reach the order of a single cell. However, the improved accuracy also results in a significant decrease in forming efficiency, and this process is also difficult to print viscosity Higher biological materials reduce their ability to print three-dimensional biological structures [4]. The representative research institution is Professor David Odde’s research group from the University of Minnesota.

Stereo Lithography Cell 3D Printing Technology

The three-dimensional lithography cell three-dimensional printing technology realizes the three-dimensional solidification and shaping of the photoresist-containing cells through the scanning movement of laser or ultraviolet light in space and creates a pre-designed three-dimensional biological structure [5]. Although this technology is highly flexible, its molding efficiency is not as good as expected. Some researchers no longer use the small laser spot to scan the three-dimensional curing forming but use the principle of the projector to perform surface projection, and each layer is cured and formed at the same time. According to the type of projector, the process can be divided into LCD projector type and DMD projector type.

The essential difference between the two is that the LCD projector first decomposes the light source into 3 kinds of monochromatic light, and then the brightness of the three types of monochromatic light is controlled by three liquid-crystal panes respectively to synthesize the required light and pattern, while DMD only uses a digital array microscope of can reflect the light source to achieve. The photosensitive hydrogel of process is pre-stored in the forming chamber, which cause material waste, and it is difficult to produce a variety of cell heterogeneous structures, and most of the photosensitive hydrogels have different degrees of toxicity to makes cell survival rate are modest. The representative research institutions are Chen Shaochen’s research group at UCSD.

Acoustic-driven cell printing technology

Acoustic-driven cell printing technology is a method that uses the vibration of sound waves to generate droplet ejection, and its accuracy can be as low as about 10 μm. However, this process is also a droplet ejection method, and it is difficult to eject high-viscosity biological materials, making it possible to print three-dimensional biology The capabilities of the structure are limited [6]. Representative research institutions include Professor Demirci’s research group from Stanford University in the United States.

In summary, various cell printing methods have their own strengths, but for three-dimensional complex heterogeneous biological structures, micro-extrusion cell three-dimensional printing technology is more suitable, and it is easier to construct multi-cell three-dimensional models. The efficiency is higher, the cell survival rate is high, and the printing accuracy (100 microns) can also meet the needs of general scientific research. Therefore, the current mainstream cell 3D printers on the market are mostly based on this technology. Representative companies include Envision TEC in Germany, RegenHu in Switzerland, SunP Biotech in China, and Genova, etc.

The future of cell 3D printing

Although currently, cell 3D printing can print a variety of cells, it can even construct some simple tissues. However, it is still a long way from organ printing. In the future, it is worth paying attention to several research breakthroughs or trend changes in order to promote the forward development of cell 3D printing technology.

Research new bio-ink

At present, most bio-inks have advantages and disadvantages, and there is no ideal type of bio-ink. Inks based on natural biological materials have good biocompatibility, but most of them are difficult to print or have poor mechanical properties. The ink printing performance or mechanical performance based on synthetic polymer materials is better, but the biological activity is generally poor, and even some materials have not been FDA certified. In the future, it will be an inevitable trend in the industry to develop bio-inks with both excellent printing performance and biological performance.

Industrialization promotes the rapid advancement of the entire field

As the industrialization of biological 3D printing continues to mature, more and more manufacturers have begun to develop commercialized biological 3D printers, which are becoming more powerful and cheaper. This allows researchers who are new to this interdisciplinary field, especially those who are not mechanical and electronic professionals such as materials scientists, biologists, and doctors, to focus on bio-inks without having to spend their energy in the field of printer development that they are not good at. Research and development and construction of tissues or organs. Therefore, the industrialization of cell 3D printers is promoting faster development in this field.

Providing professional services for cell 3D printing will be the future trend

The interdisciplinary characteristics and technical challenges of cell 3D printing determine its threshold for entry. By cooperating with experienced scientific research institutions, or looking for experienced companies for technical services, newbies will quickly obtain knowledge and a convenient way to obtain scientific research results. Based on this prediction, there will be more and more specialized service companies for cell 3D printing with a university research background. university research background.

Conclusion

In recent years, with the industrialization of biological 3D printer and biological ink, cell 3D printing technology has entered more and more laboratories, and more researchers in cross fields have joined in this field to realize the dream of human organ reconstruction. It is believed that with the continuous vigorous development of cells 3D printing, the day of organ printing will not be far away.

Reference

[1] Saunders R E, Gough J E, Derby B. Delivery of human fibroblast cells by piezoelectric drop-on-demand inkjet printing. Biomaterials, 2008,29(2):193-203.

[2] Khalil S, Nam J, Sun W. Multi‐nozzle deposition for construction of 3D biopolymer tissue scaffolds. Rapid Prototyping Journal, 2005, volume 11(1):9-17.

[3] Kolesky D B, Truby R L, Gladman A S, et al. 3D Bioprinting of Vascularized, Heterogeneous Cell‐Laden Tissue Constructs. Advanced Materials, 2014,26(19):3124-3130.

[4] Odde D J, Renn M J. Laser‐guided direct writing of living cells. Biotechnology & Bioengineering, 2000,67(3):312-318.

[5] Itoga K, Kobayashi J, Yamato M, et al. Maskless liquid-crystal-display projection photolithography for improved design flexibility of cellular micropatterns. Biomaterials, 2006,27(15):3005-3009.

[6] Yu Fang J P F S. Rapid Generation of Multiplexed Cell Cocultures Using Acoustic Droplet Ejection Followed by Aqueous Two-Phase Exclusion Patterning. Tissue Engineering Part C Methods, 2012,18(9):647-657.

[7] Zhao, Y, Yao, R, Ouyang, L, et al. Three-dimensional printing of Hela cells for cervical tumor model in vitro. Biofabrication, 2014, 6(3): 035001.

[8] Lee K Y, Mooney D J. Alginate: Properties and biomedical applications. Progress in Polymer Science, 2012,37(1):106-126.

[9] Mosesson M W. Fibrinogen and fibrin structure and functions. Journal of Thrombosis & Haemostasis, 2005,3(8):1894-1904.

[10] Billiet T, Gevaert E, De Schryver T, et al. The 3D printing of gelatin methacrylamide cell-laden tissue-engineered constructs with high cell viability. BIOMATERIALS, 2014,35(1):49-62.